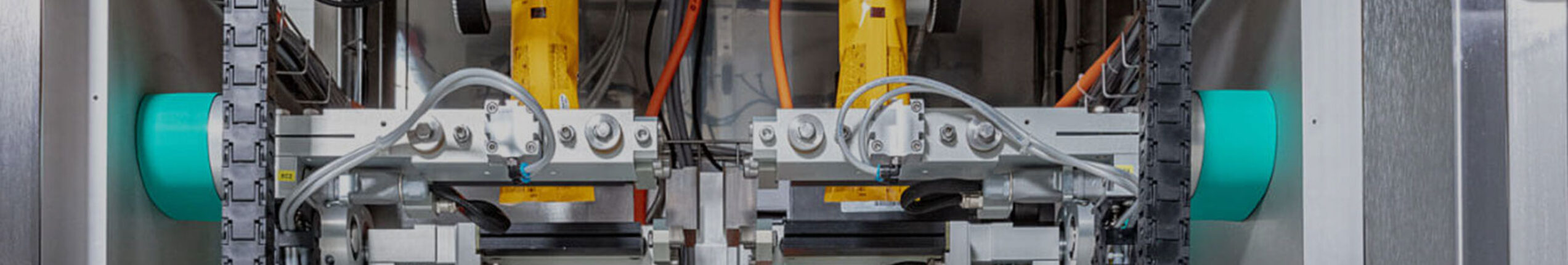

Automatic friction feeder.

Automatic Friction Feeder for Various Applications

Discover the versatility of the FR100 Automatic Friction Feeder. This revolutionary feeder offers effortless feeding of flat products such as pouches, pouches, leaflets, flat boxes, and more. With the FR100, you can make your production process significantly more efficient thanks to automatic labelling, printing, and counting of products. Easy to adapt to your specific needs, this user-friendly feeder can be seamlessly integrated with your existing machines for fully automated product feeding.

Our friction feeder is ideal for various industries and applications. The FR100 can be equipped with labelling machines for both bottom and top labelling of bags, as well as printers for direct printing. See here an example that we can offer as a standard system.

Advantages

- User-friendly: Settings are provided with readouts by rulers or other numbers, ensuring quick and accurate adjustments.

- Reliability: High-quality construction and components ensure a long service life and minimum downtime.

- Versatile: Suitable for various sizes and different thicknesses.

- Material types: Processes materials such as paper, cardboard, plastic, and more with high precision.

- Energy-saving: Efficient energy consumption contributes to lower operating costs.

Application examples

- Food industry: Ideal for feeding pouches or automatically labelling pre-made pouches.

- Pharmaceutical Industry: Suitable for handling medicine packaging and information leaflets.

- Logistics and E-commerce: Automatic feeding of shipping labels and promotional leaflets.

Integration and Compatibility

The FR100 can be easily integrated into your existing production line and is compatible with a wide range of label machines and printers. This ensures a seamless transition and optimal efficiency in your production process. See here An example where the feeder has been used as a pouch feeder.

Feel free to contact us for more information on how the FR100 Automatic Friction Feeder can optimise your production process.

Specificaties

-

Capaciteit180 per minute

-

Minimum dimensions140x80mm

-

Minimum dimensions400x300mm

Requesting information

Whitepaper applications