Automatic labelling machine for Bags, Pouches and Planos

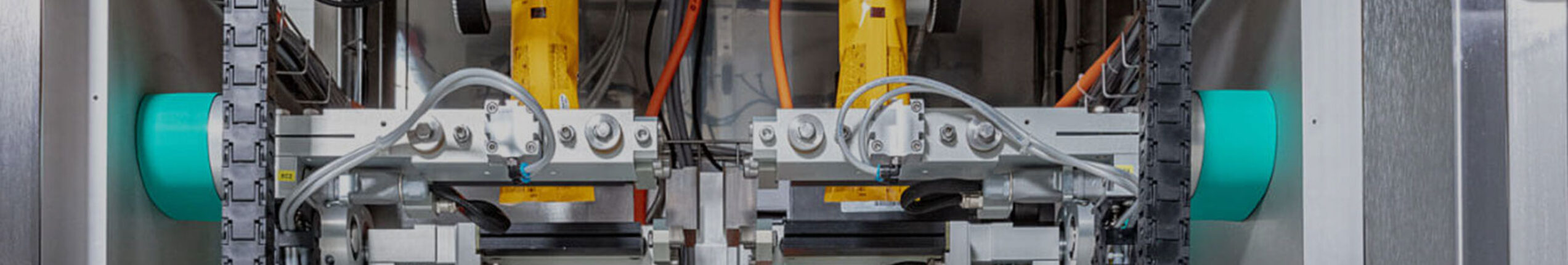

The FRL (Feeder with labeller for labelling on one side) and FRDL (Feeder with two labellers for labelling on both sides) are the ideal solutions for efficient and accurate labelling of flat packs such as pre-made pouches, pouches, leaflets and planos.

With these machines, you save time and labour costs and improve the consistency and quality of your labelling. The feeder automatically feeds the packs one by one, then labels them flawlessly.

Benefits of the FRL and FRDL automatic labelling machines

- Simple operation: Adjustments can be made easily via the control panel. Mechanical adjustments feature rulers or other numbering.

- Accurate labelling: Labels are applied consistently and error-free.

- Flexible: The ability to integrate printers for direct label printing makes the FRL and FRDL versatile and adaptable to different applications.

- Durable and reliable: Solid construction and high-quality components ensure minimal downtime.

- Reliability: High-quality construction and components ensure a long service life and minimum downtime.

- Versatile: Suitable for various sizes and different thicknesses.

- Material types: Works with materials such as paper, cardboard, plastic and more with high precision.

- Possibility of printing: Combine the labelling system with printers for printing barcodes, best-before dates or batch codes.

Application examples

- Food industry: Suitable for pre-made pouches and pouches (see here a sample video)

- Petfood: Ideal for labelling pet food packages that are currently labelled manually.

- Pharmaceutical Industry: Efficient labelling of medicine packaging and information leaflets.

- Logistics and E-commerce: Automatic labelling of advertising and promotional leaflets.

- Pre-made pouches labelling: Automatic labelling of pouches with, for example, a zip closure.

Why choose the FRL and FRDL?

The FRL labels one side at a time, while the FRDL labels both sides at the same time. With these machines, you not only save time, but also optimise your production process and improve the quality of your labelling.

✔ Less downtime thanks to reliable construction.

✔ Time savings by automated labelling.

✔ Easy integration in existing production lines.

Feel free to contact us for more information on how the FRL and FRDL Automatic Label Machines can optimise your production process. Our experts are ready to answer all your questions and help you choose the right solution for your specific needs.

Specificaties

-

Capaciteit180 per minute

-

Minimum dimensions140x80mm

-

Maximum dimensions400x300mm

Requesting information

Whitepaper applications