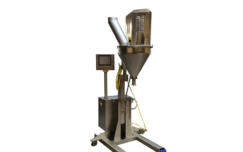

Dosing screw for powders and granules.

We overhauled this metering screw and developed an entirely new controller. We also made a special movable frame that fits perfectly under our customer's machine. These modifications were tailor-made to meet the customer's specific requirements and needs.

The dosing screw is designed with adjustable height, giving the user the flexibility to set the right position for optimal dosing. Via a large HMI screen, all speeds and quantities can be easily set. This ensures precise control over the dosing process and offers the option of manual dosing or working in line with other machines.

To improve efficiency, we have integrated automatic signals. For instance, the user receives notifications when the hopper becomes empty so that another process can automatically refill it. In addition, the user receives a signal when dosing is complete, allowing the machine underneath to move directly to the next step.

With these improvements, we have not only ensured an optimised dosing process, but also seamless integration with other systems and machines. We aim to provide tailor-made solutions that meet the specific needs of our customers, and with the new controller and movable frame, we have achieved this goal.

Our dedicated commitment to quality, innovation and customer satisfaction has resulted in a successful partnership with our customer. We remain committed to delivering solutions that contribute to more efficient and optimised operation of their processes.

Over dit project

Sector

- Food

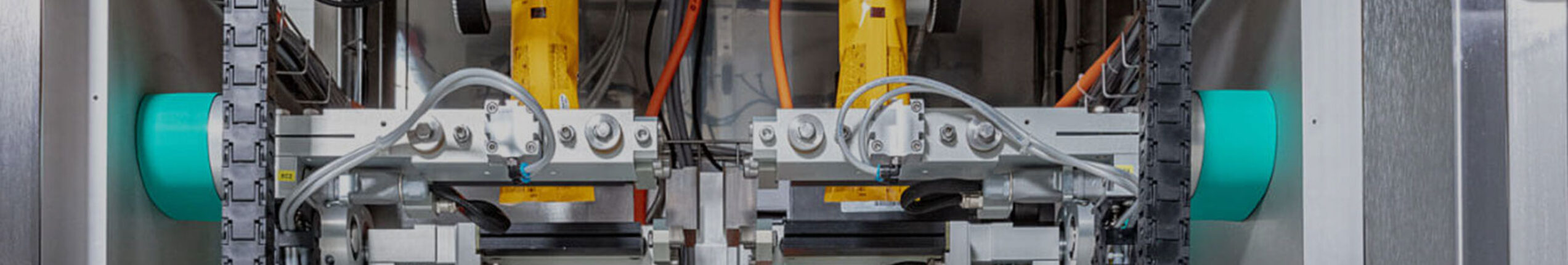

Machine

- Dosing screw

Locatie

Vertical form fill and seal machines SE300 Budget servo

Viking Masek SE300 Vertical form fill and seal machine. The Budget Servo VVVS machine. With broad technical expertise, we designed the new SE300 packaging machine. This machine has a robust stainless steel construction and is equipped with a servo drive. It is the perfect and affordable solution for customers who...

Onze producten