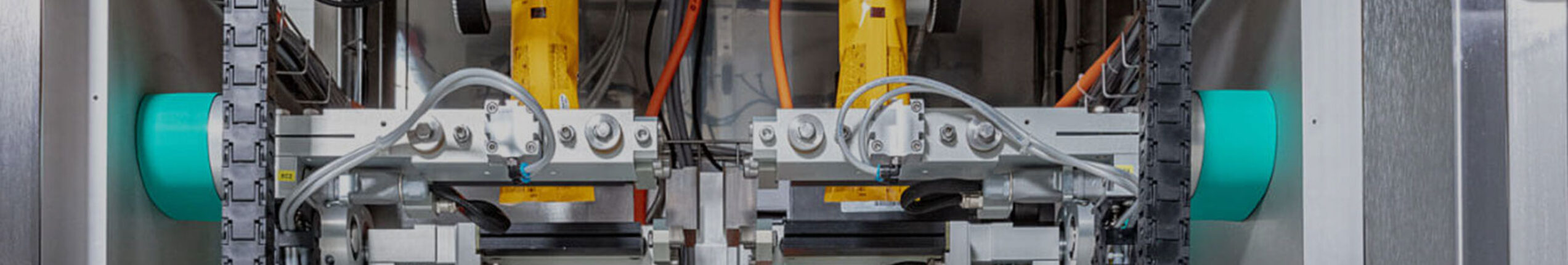

Semi automatic tubefiller

This tube filler is equipped with an advanced weighing system with an impressive resolution of 0.001g, ensuring accurate weighing of both the tube and its contents during different stages of the production process. This precision weighing ensures high quality control and consistent results.

The process starts by weighing the tube including the cap. Next, the beads are individually dosed and weighed. This is followed by the dosing of the liquid, after which the tube is weighed again. If a tube falls outside the preset tolerance, it is automatically rejected to ensure strict quality control.

When a tube is approved, a barcode is generated and printed, which is then affixed to the tube. Each filling weight is accurately logged and linked to the corresponding barcode, ensuring full traceability and archiving of product data.

Our continuous commitment to innovation and quality enables us to implement the latest technologies and meet the high demands of the industry. We remain focused on improving our processes and delivering products of the highest standard to meet our customers' expectations.

Over dit project

Sector

- Medical

Machine

- Tubefiller

Locatie

Tube labelling machine TLM60

TLM60 Tube Labelling Machine - Efficient and Accurate Labelling of Tubes The TLM60 tube labelling machine is an advanced solution for automatic labelling of tubes. The machine is designed for fast and accurate labelling of tube containers, collection tubes and laboratory tubes. This makes the TLM60 ideal for applications in cosmetic, pharmaceutical,...

Onze producten